Hours:

8:30am – 4:30pm CST

Monday thru Friday

We started American Canning for one reason – to provide craft consumers greater access to the beverages they love most. Our equipment, supplies and mobile canning services break down barriers to packaging with low minimum quantities, affordable pricing, quick lead times and easy online ordering.

We’re in it for the love of craft and helping beverage makers share their craft in cans.

Why We Can

We envision a marketplace where every beverage brand, no matter how big or small, can be represented in cans. Whether you’re producing craft beer, wine, mead, cider, coffee, tea, kombucha, soda, water, juice, or any other delectable drink, we’d be honored to work with you.

Bringing Convenience to Canning

Ordering supplies shouldn’t be difficult. That’s why we developed this site and eliminated extravagant minimum order quantities. You can order as many or as few supplies as you want, whenever you need.

We stock most of our items to be able to ship the same day. For custom items such as shrink-sleeve cans, we work with a network of suppliers to ensure you receive the fastest and most cost effective delivery possible.

Low Cost Products, High Quality Service

Affordable pricing doesn’t mean cheap customer service. In fact, it’s just the opposite. We’re committed to ensuring you have the highest quality experience with our team. If there is ever anything we can do to improve the process, drop us a line and let us know.

Together, we can. That’s our commitment to being your packaging partner.

We’re headquartered in Austin, Texas, USA, but we work with customers throughout the globe. Regardless of where you are or what beverage you produce, we’re committed to being a valuable resource for you and your brand(s).

On behalf of everyone at American Canning – cheers!

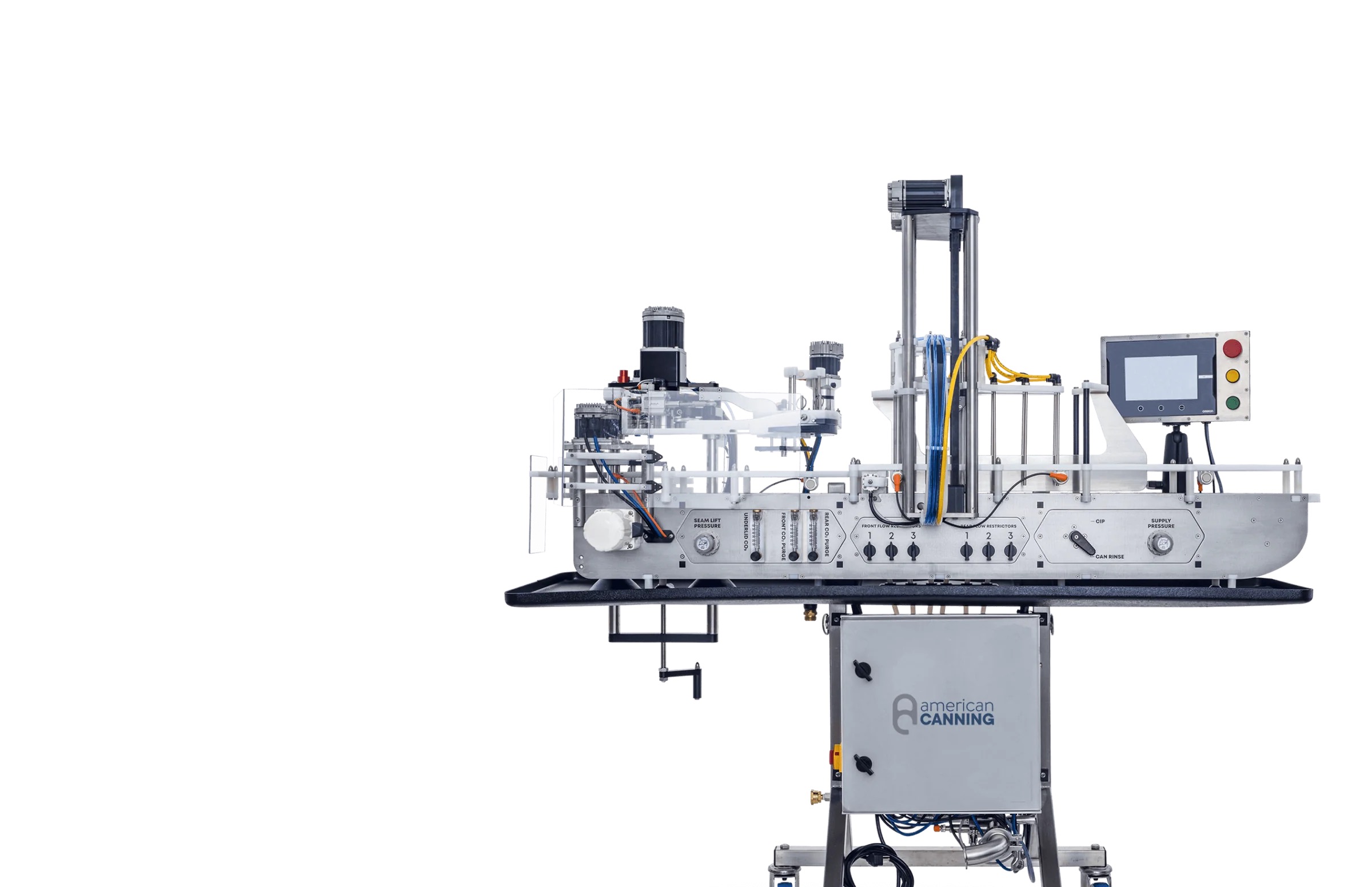

- Integrated in-feed/out-feed table

- Pre-purge and underlid gassing

- Stainless steel fill-head

- Precision-adjust flow restrictor

- Rotary-style lid applicator

- Servo-driven seamer

- Post-fill rinse

- Wash-down rated

- Keg adapter for easy pull from tanks or kegs

Fill Method: Atmospheric

Speed: 8-12 CPM

Footprint: 24” x 40”

Liquid: Carbonated

Can Styles: Standard, Sleek, Slim

Can Fill Height: 87mm to 188mm / 8oz to 19.2oz standard 211-diameter fill volume cans

Carbonation: 2.8 volumes CO2 at 33F max

Temperature: 35F at 2.5 volumes CO2 max

Power: 110-120V/60 Hz OR 220-240V/50 Hz

Compressed Air

Pressure: 100-170 PSI

Flow Rate: 1 scfm at 90 PSI

C02 pressure: 15-25 PSI

Water: ¾” hose

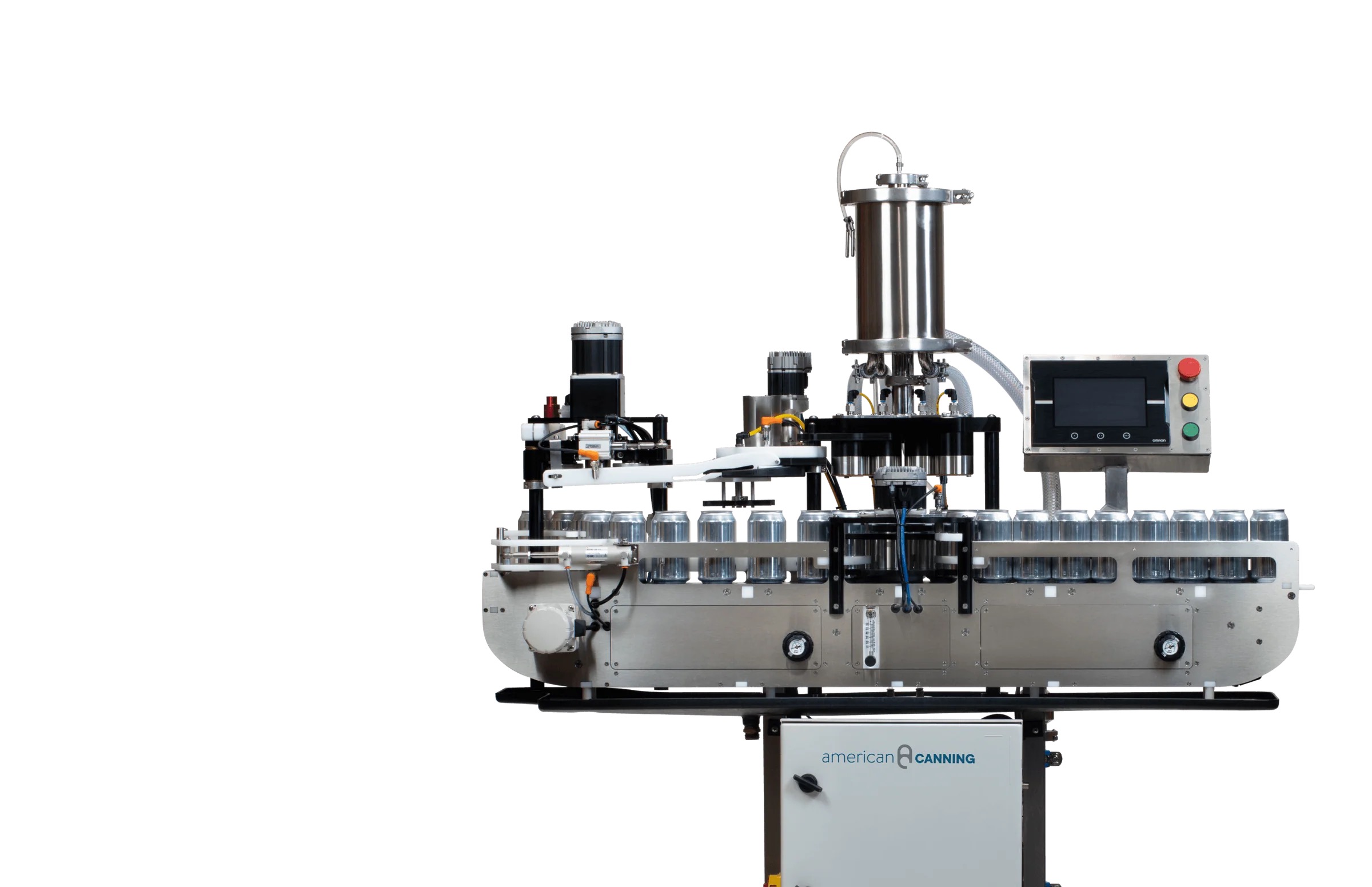

The CP-4 grants users versatility in product packaging without the cumbersome user experience or typical complications of larger-scale counterpressure filling. The CP-4 is a four-head system with counterpressure capabilities that has been simplified to give small-to-mid scale producers access to 20-30 cans per minute in nearly any fill volume at 30-50 PSI. Its intuitive user interface is easy to learn and allows operators to quickly align filling parameters to a specific product state. With its modern, open design, users will find the machine easy to access, changeover, and maintain. Incorporated head pressure control and intermittent filling ensure maximum product quality with minimum loss or waste. The CP-4 is best suited for beverages makers producing more than one type of product, or desiring more flexibility in the production and packaging parameters.

- Approachable user interface for any experience level

- One to two operators design

- Built-in head pressure control

- Pre-purge and underlid gassing

- Stainless steel fill valves for longevity and easy serviceability

- Intermittent fill system for reduced product waste

- Rotary-style lid applicator

- High-power, servo-driven seamer

- Post-seam rinse and air knife clean

- Automatic CIP cycle

- Wash-down safe rated

- Keg adapter for easy pull from tanks or kegs

Fill Method: Counterpressure

Speed: 20-30 CPM

Footprint: 55” x 20” x 40″

Liquid: Carbonated and Still

Can Styles: Standard, Sleek, Slim

Can Fill Height: 87mm to 188mm / 8oz to 19.2oz standard 211-diameter fill volume cans

Carbonation: 2.8 volumes CO2 at 33F max

Temperature: 35F at 2.5 volumes CO2 max

Power: 110-120V/60 Hz OR 220-240V/50 Hz

Compressed Air

Pressure: 115-180 PSI

Flow Rate: 15 scfm at 90 PSI

CO2 pressure: 60-90 PSI

Water: ¾” hose